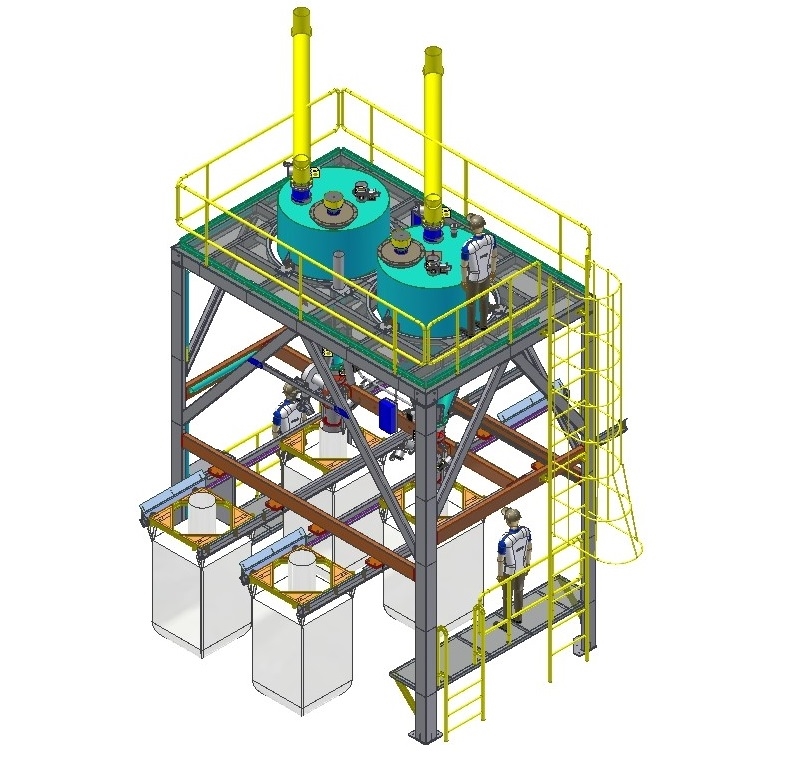

BIG-BAG FILLING MACHINE

It is designed for filling powder and granular materials in desired set values into big-bag sacks

Working principle of the big-bag filling machine consisting of pre-feed unit, weighing hopper, load cells, big-bag connection group, pneumatic cylinders and product discharge outlet;

The weighing hopper is filled with the set screw conveyors at the specified set value, connected to the big-bag discharge outlet and the dust collection system is activated, the big-bag is inflated with the help of the fan before the discharge, and when the filling starts, the rotten air in the bag and the dust formed in the environment are absorbed for quick and easy filling

| Advantages and Equipment |

|---|

| 20-120 t/hour capacity according to customer request |

| IP65 protected panel and operator panel with touch screen |

|

Weighing system capable of weighing with ± 0,5% precision

|

| Chassis suitable for big-bag transportation by using forklift or crane |

| Bag inflation system for fast and efficient filling |

| Filtration system preventing dusting |

| Emergency notification |

| Automatic and manual operating modes |

| Profibus, Profinet, Hardwire communication infrastructure |